Smart Weld 3D for Creo

3D Weld Geometric Data in a Flash

SmartWeld 3D, a Creo solution, allows users to quickly and efficiently add 3D weld information to their designs by capturing and implementing company design and manufacturing standards.

Key Features

- Quickly build weld trajectories on the fly using existing geometry.

- Define the weld type, size, etc.

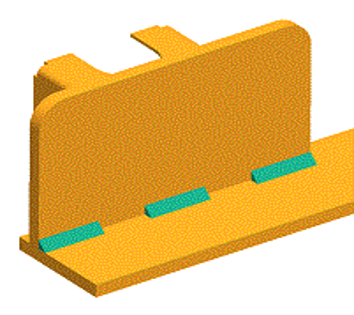

- Any weld type can be made available including fillet, groove, and spot welds.

- Continuous, intermittent, dual-side, and non-standard weld types are supported.

- Information can be outputted in a variety of ways for end users and manufacturing processes.

- Automatically generates 2D weld symbols and data for robotic welding.

How It Works

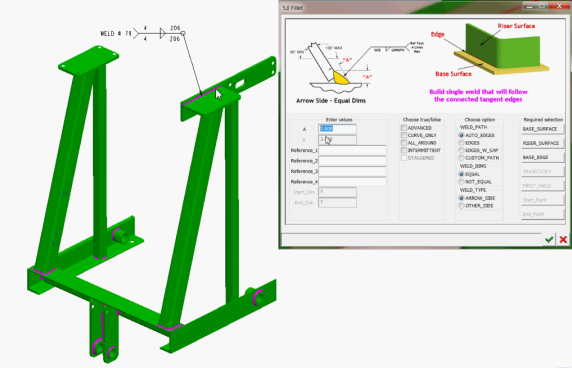

- User defines the start and end of the weld.

- User is presented with a variety of inputs and guides based on existing model geometry

- User makes selections, and all necessary weld geometry is created on the fly by SmartWeld.

- SmartWeld leads users in generation of 3D weld data.

- Weld symbols are created on the fly, and data is fully parametric.

- Generates weld parts where weld geometry is stored.

Key Benefits

- Rapid customization to meet the needs of your company.

- Eliminate guess and design errors when designing welds.

- 2D weld symbols provide accurate visual cues and exact measurement data for manufacturing.

- 3D geometry provides accurate volume and weight calculations.

- Produces NC paths for robotic welding directly from existing geometry.

- Costing can include more accurate variables.