SmartElectrode for Creo

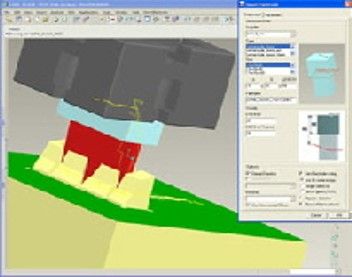

SmartElectrode is software developed for Creo that automates all aspects of extraction, design, management, documentation and manufacturing of EDM electrode. Through its GUI-driven process, SmartElectrode guides the user through the electrode design and production process. The user simply deals with the electrode design; the burn setup sheets, and optionally the electrode drawings and machining files are all created automatically.

The GUI and process are simple while at the same time flexible, offering for the first time a sophisticated electrode design software for Creo. Within a few minutes, a complex cavity in a model is automatically extracted to form a fully featured Creo model of the electrode, along with its holder, electrode drawings, setup sheets and tool paths.

Key Features

- Automatic electrode extraction

- Automated initial electrode placement based on selected burn feature

geometry - Exact placement and orientation of electrode

- Standard catalogs of electrode blanks and holders - fully customizable and extendable

- Single and multi-extract electrode assemblies

- Multi-placement of the same electrode

- Full control of burn surface and electrode refining through easy to use GUI

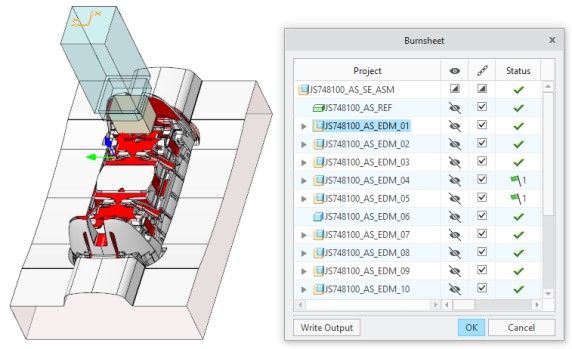

- Automatic generation of burn setup sheets and electrode drawings

- Automatic creation of Pro/NC machining files

- Graphical display of burn areas where electrode are already designed

- Display animation of EDM burn cycle

How It Works

- Choose a holder and electrode blank from the available library (user extendable)

- Graphically position, orient and fine-tune the electrode placement. The extraction is done automatically

- Detail-design the electrode using the GUI to tweak the burn areas and neighboring areas.

- Setup sheets, electrode drawings and manufacturing files are created automatically.

Key Benefits

- Significant savings over the use of Creo alone

- Consistent quality – all electrode creation follows the same process and

feature map - Organizes multi-electrode jobs – eliminates electrode setup problems

- Precise control of extension surface details gives excellent EDM surface quality

- Immediate burn setup sheets and electrode drawings

- Automation and organization of the process minimizes costly mistakes

- Eliminate repetitive tasks such as creating electrode drawings, setup tables, etc.

- Automatic machining setup with Pro/NC practically eliminates NC programming lead-time

- Easy to learn logical process with a dynamic and easy to use interface offering unrivaled flexibility

Enforce company standards - Define standard rules per company, project or customer. Automatically set naming convention, colors, layers, default values and drawing formats.